Materials Test Lab Proficiency: Elevate Your Item Integrity

Wiki Article

Comprehensive Materials Testing Services for Quality Control

In today's competitive market, making sure the top quality and reliability of materials is essential for the success of any job or product. Extensive materials testing solutions play a pivotal duty in attaining this goal. These solutions incorporate a series of tests and evaluations that evaluate the toughness, resilience, chemical make-up, and efficiency of materials. materials test lab. By using non-destructive screening approaches and conducting environmental and weathering tests, prospective weak points or susceptabilities can be recognized and addressed proactively. In addition, product failure evaluation permits a much deeper understanding of why products may not fulfill the wanted criteria, leading to enhanced quality assurance measures. With a careful and professional strategy, detailed materials testing solutions offer vital support to industries across numerous markets, ensuring the honesty and quality control of structures, products, and products.Toughness and Sturdiness Checking

Strength and resilience testing is a vital action in making sure the high quality and reliability of products, as it permits the evaluation of their capability to stand up to outside pressures and ecological problems. This kind of testing is crucial in various industries, consisting of building and construction, automobile, aerospace, and production.During stamina testing, materials undergo different sorts of pressures, such as tension, compression, shear, and bending, to determine their mechanical residential or commercial properties and resistance to deformation. This assists makers understand how materials will perform under real-world problems and make notified decisions concerning their suitability for details applications. By gauging criteria like return stamina, supreme tensile strength, and modulus of elasticity, engineers can analyze the product's performance and guarantee it fulfills the called for criteria.

Chemical and Structure Analysis

Chemical and composition analysis is a vital facet of products screening, continuing the examination from the previous subtopic by analyzing the important make-up and molecular structure of products. This analysis provides important insights into the chemical residential or commercial properties and composition of a product, which is vital for recognizing its habits and efficiency in numerous applications.One essential aspect of chemical and structure evaluation is the recognition and metrology of components existing in a material. This details assists identify the important make-up and purity of the product, guaranteeing it meets the required standards and specs. Additionally, it permits the discovery of pollutants or trace components that might impact the material's buildings or efficiency.

Furthermore, chemical and structure evaluation can provide information concerning the molecular framework of a product. This includes the plan and bonding of atoms, which influences the material's chemical and physical buildings. By understanding the molecular framework, scientists and engineers can make informed choices regarding the viability of the product for specific applications and identify any type of potential weaknesses or vulnerabilities.

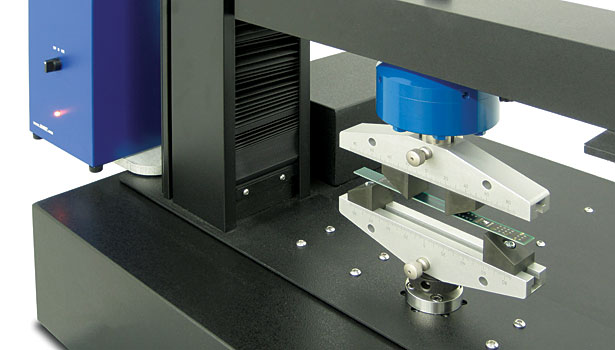

Non-Destructive Checking Approaches

Environmental and Weathering Testing

Environmental and weathering screening plays an important function in evaluating the longevity and performance of materials in different problems. materials test lab. This sort of screening is vital in determining exactly how materials will hold up against exposure to various environmental aspects, such as temperature level, moisture, UV radiation, and chemicals. By subjecting materials to these problems in a controlled laboratory setting, suppliers can acquire important insights into their lasting performance and make informed choices about their suitability for certain applicationsOne of the crucial advantages of environmental and weathering screening is that it allows suppliers to examine the impact of these variables on the physical, mechanical, and chemical buildings of products. Exposure to high temperatures can create products to increase or agreement, leading to dimensional changes and potential failure. Long term exposure to UV radiation can create products to weaken and lose their architectural honesty. By replicating these problems busy, suppliers can identify possible weak points and make needed enhancements to make sure the long life and dependability of their items.

Along with examining the durability of materials, environmental and weathering testing likewise helps suppliers follow market criteria and guidelines. Several sectors, such as auto, click now aerospace, and building and construction, have particular needs for products made use of in their products. By carrying out testing according to these requirements, makers can show the high quality and integrity of their products, giving clients self-confidence in their products.

Material Failing Evaluation

The analysis of product failing is an integral part of detailed products examining go to these guys solutions for quality control. Material failing can take place due to various elements such as layout imperfections, making defects, incorrect usage or upkeep, and ecological conditions. The purpose of material failing analysis is to determine the source of the failing and supply insights for enhancing the product's efficiency and toughness.Material failure analysis involves an organized technique that includes visual examination, non-destructive screening, and lab screening. Lab screening involves carrying out various tests, such as mechanical screening, chemical evaluation, and microstructural analysis, to understand the product's attributes and buildings.

By examining product failings, suppliers can determine powerlessness in their products and make needed improvements to stop future failures. This assists in making certain the quality and dependability of the products made use of in different sectors such as auto, aerospace, construction, and electronic devices. Additionally, product failing analysis plays an essential role in item development and quality assurance, as it helps in choosing the right materials and maximizing their performance.

Verdict

To conclude, comprehensive products evaluating services are important for high quality assurance. These solutions include toughness and sturdiness testing, structure and chemical evaluation, non-destructive screening approaches, environmental and weathering testing, and material failing evaluation. By making use of these testing methods, business can guarantee the top quality and reliability of their materials, leading to enhanced product efficiency and consumer fulfillment.Product failing analysis allows for a much deeper understanding of why materials may not satisfy the wanted criteria, leading to boosted high quality control steps. With a thorough and expert technique, comprehensive materials screening services give vital assistance to industries across numerous sectors, assuring the honesty and high quality assurance of items, materials, and structures.

The analysis of material failing is an important component of detailed products checking solutions for top quality assurance. The function this website of material failure evaluation is to identify the origin reason of the failure and provide understandings for improving the product's performance and toughness.

Furthermore, product failure analysis plays a crucial role in item advancement and top quality control, as it helps in selecting the right products and enhancing their performance.

Report this wiki page